POSCO is a steel industry pioneer with a rich history and commitment to quality and excellence.

Products

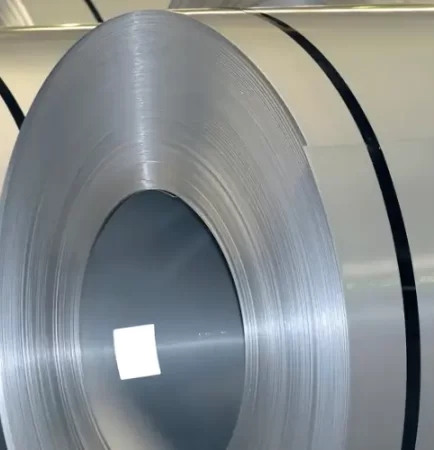

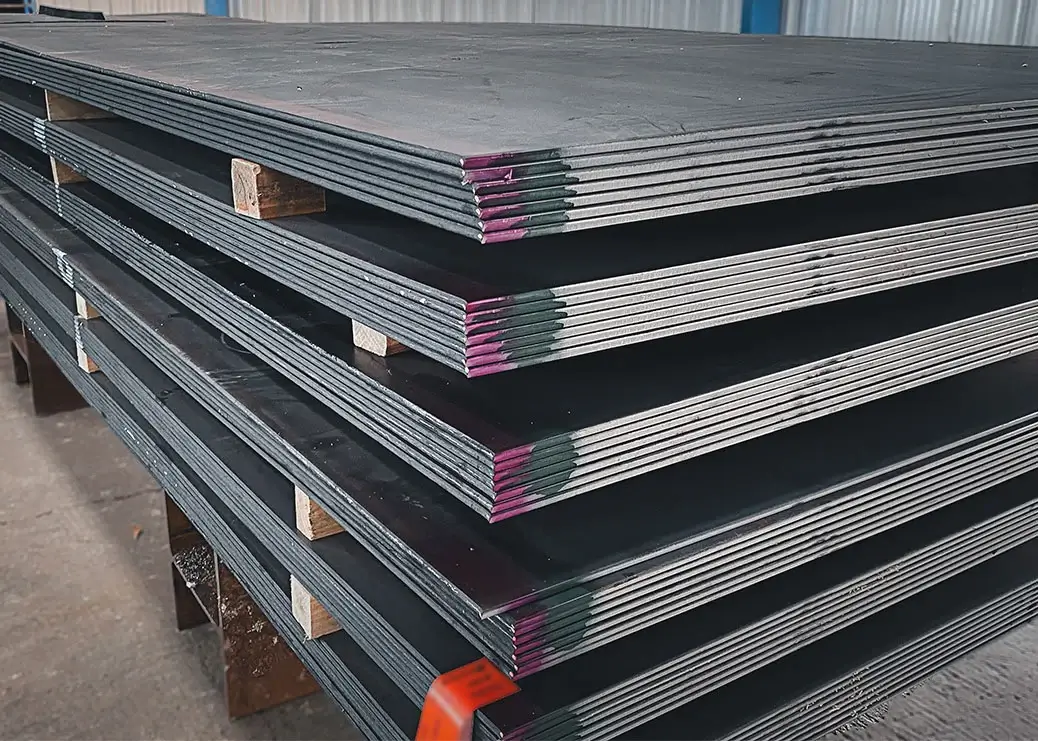

Hot Rolled Steel – HR

Cold Rolled Steel – CR/CRCA

Hot-dip Galvanized Steel – GI/CRCG

Electrical Galvanized Steel – EG

POSMAC

ALCOSTA

ALZASTA

Wire Rod

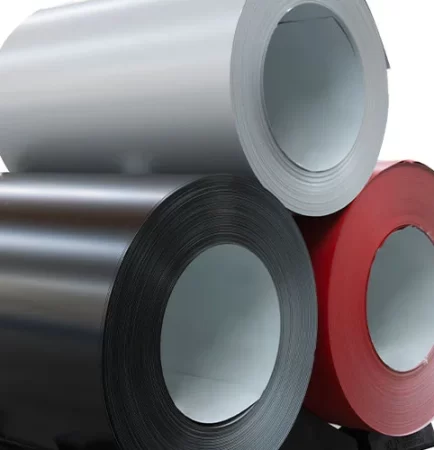

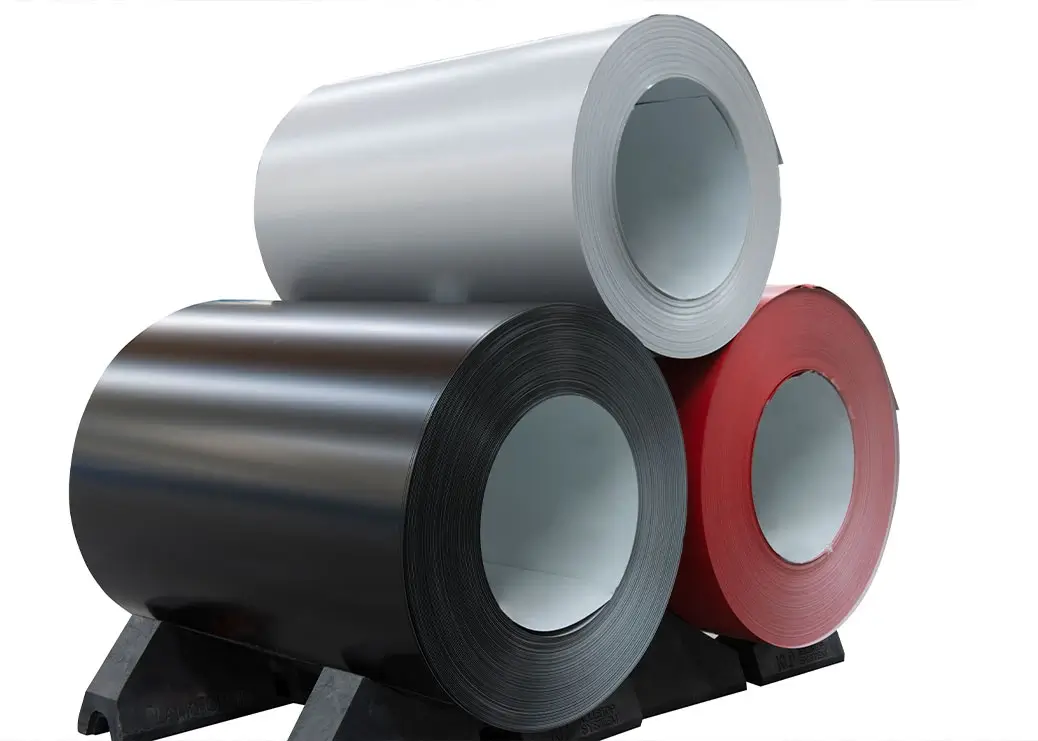

Color Coated Steel

Stainless Steel

Electrical Steel

Steel Plate

Titanium

Hot rolled products are used extensively for various applications including General Engineering, Automobile frame parts, Pipes and Tubes, Agricultural Equipment, Building Iron Structures, Bridges, Gas Containers-Cylinders, Ships Building, Machine Parts. Hot-rolled steel products are widely used in many different industries due to their high strength as well as excellent formability, drawability, weldability, machinability and corrosion resistance.

Cold Rolled Continuous Annealed Steel Coils and Sheets (CRCA) have fine surface and excellent workability. They are used for various purposes including automobiles, home appliances, furniture, office equipment, Drum, Barrels industrial machines and construction material.

Hot-dip galvanized steel products are now being used in a wide range of automobiles, electrical equipments and other industrial machinery as well as in civil engineering and construction.

POSCO GI/GP/GPSP steel products are Zero Spangle, Uniform Surface roughness, Strong Zinc bonding layer and characterized in excellent formability, weldability, paintability as well as anit corrosion, they can meet the high quality requirements of the users.

This product is made by applying galvanizing to the surface of cold rolled steel using an electrochemical method. It allows the user to choose from different post-treatment options, including non-treatment, phosphate, anti-fingerprinting.

Applications include home appliances, vehicle outer panels and construction materials.

POSMAC Steel (The Revolutionary Steel) “PosMAC® Super” is an innovative hot-dip galvanized product developed with POSCO’s unique technology. It has excellent performance even in extremely corrosive conditions and can be used for various application to expand the service life of steel structures.

The differentiated coating layer composition of Zn – 5% Mg – 12% Al achieves a corrosion resistance 10 times greater than that of conventional hot-dip galvanized steel sheets (GI). It’s good hardness and high friction factor also provide good anti-galling and workability.

Hot-dip 55% Al-Zn Alloy steel (ALZASTA) has outstanding corrosion resistance due to the strong oxide coating of aluminum and sacrificed protection of zinc. Bright gray appearance with unique smoothness, flatness, and fine spangles and Outstanding paintability.

POSCO’s wire rod products, renowned for their quality, are used in a number of areas, ranging from very basic industrial materials to specialized manufacturing facilities equipment. Through the use of cutting-edge facilities and automated systems, POSCO maintains consistent efforts in the development and manufacture of higher quality wire rod products.

PPGI (Pre-Painted Galvanized Iron) steel coil is a high-quality metal material widely used in construction, home appliances, Automobile and industrial applications. It is typically cold-rolled or hot-rolled steel undergoes galvanization and coated with one or multiple layers of colourful paint.

POSCO operates an integrated production system that ranges from steel making to hot rolling and cold rolling, producing two million tons of stainless steel products every year. Stainless steel products can be classified into austenitic stainless steel, ferritic stainless steel and martensitic stainless steel according to their alloy components and tissue structure.

POSCO produces over 1 million tons of electrical steel sheets every year. The non-grain oriented electrical steel has a different, non-uniform crystal orientation. Its main applications include products containing rotating parts, such as motors and generators. Grain oriented electrical steel has a uniform crystal orientation, featuring a much higher magnetic performance.

Steel plates are hot rolled products that have a relatively high thickness. Products having a thickness of over 4.5 mm are classified as steel plates, and those having a thickness of over 100 mm are called thick steel plates. Slabs of steel plates made through continuous casting are tailored to the dimensions specified by the customer through rolling and cooling before being cut into their final sizes.

Featuring white metallic gloss, titanium is light, extremely strong and highly resistant to corrosion. Its main applications include shipbuilding, power generation and medical devices.

POSCO makes one of the best titanium products in the world based on its technological capability garnered from steel and stainless steel making.

Services

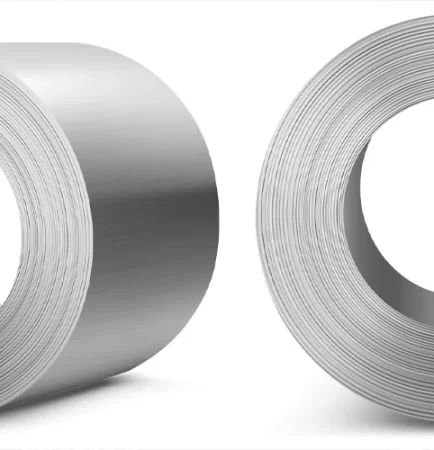

Slitting is a sheet metal cutting process with circular knives, which is used to split wide steel coil into narrower width along the length & recoil it into coil form.

Shearing is a process in which a roll of material (coil) is cut into sheets of required length or pitch. During this process, the material is cut across the rolling direction of input coils.

Blanking is a process in which a roll of material (coil) is cut into angular sheets / profile blanks of required shape with the help of metal dies. During this process, the material is cut across the rolling direction of input coils along with piercing of holes / offcuts as per final part design.

Cut to Length or Lamination Cutting a process in which a CRGO (Cold Rolled Grain Oriented) Steel roll (Slit coil) is cut into angular sheets / blanks of required shape as per transformer core / reactor core design.

Processing center products mainly consists of Coils, Sheets or Blanks. To ensure that processed material reaches safely to the end customer, proper packaging of such products is a necessary activity.

POSCO-IPPC receives the input materials (steel coils / plates) from POSCO HQ steel mills via sea route to Mumbai port & then by road transport from Mumbai port to the processing centre. Also for local steel mill (POSCO-Maharashtra), the raw materials are transferred by road transport.

Slitting is a sheet metal cutting process with circular knives, which is used to split wide steel coil into narrower width along the length & recoil it into coil form.

Shearing is a process in which a roll of material (coil) is cut into sheets of required length or pitch. During this process, the material is cut across the rolling direction of input coils.

Blanking is a process in which a roll of material (coil) is cut into angular sheets / profile blanks of required shape with the help of metal dies. During this process, the material is cut across the rolling direction of input coils along with piercing of holes / offcuts as per final part design.

Cut to Length or Lamination Cutting a process in which a CRGO (Cold Rolled Grain Oriented) Steel roll (Slit coil) is cut into angular sheets / blanks of required shape as per transformer core / reactor core design.

Processing center products mainly consists of Coils, Sheets or Blanks. To ensure that processed material reaches safely to the end customer, proper packaging of such products is a necessary activity.

POSCO-IPPC receives the input materials (steel coils / plates) from POSCO HQ steel mills via sea route to Mumbai port & then by road transport from Mumbai port to the processing centre. Also for local steel mill (POSCO-Maharashtra), the raw materials are transferred by road transport.